|

Anping Ofolan Metal Wire Mesh Manufacture Co.,Ltd

|

Molybdenum mesh|molybdenum wire mesh|high temperature molybdenum screen

| Price: | 350.0~3300.0 USD |

| Payment Terms: | T/T,L/C |

| Special Groups: |

Molybdenum mesh|molybdenum wire mesh|mol (1)

|

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

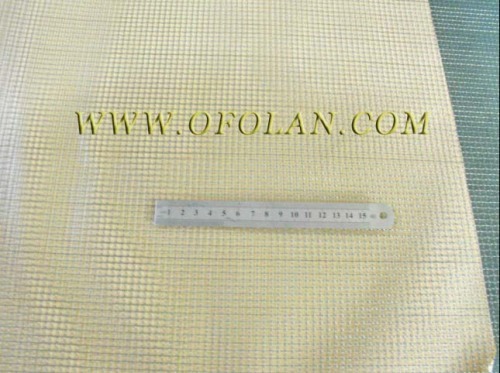

Molybdenum mesh|molybdenum wire mesh|high temperature molybdenum screen

Molybdenum wire diameter: 0.02mm-2.0mm

Specifications: 4 --280 mesh size

Molybdenum mesh|molybdenum wire mesh|high temperature molybdenum screen

Molybdenum wire diameter: 0.02mm-2.0mm

Specifications: 4 --280 mesh size

Weaving: plain weave, twill weave

Features: Black molybdenum wire -- pure molybdenum, the surface of graphite coating

White molybdenum wire -- the removal of MO1 surface coating, and has good surface

Molybdenum wire mesh spot goods: 5 mesh, 10 mesh 20 mesh, 40 mesh, 60 mesh, 80 mesh, 100 mesh, 150 mesh, 250 mesh . molybdenum wire mesh have stock in our company all the year round, has to meet the experimental unit of small batch orders and large industrial units needed to schedule, save you individually customized high cost and long time cost. Special specifications can be to sample processing customized according to the requirements of the drawings.

OFOLAN MESH provides molybdenum wire mesh purity was 99.95%, Product surface mesh is even, no broken wires, no loophole, molybdenum, melting point 2640 ℃, with very high resistance to high temperature performance, therefore molybdenum net is applied to corrosion in the production of connectors, high temperature working environment structure, heating element, IC, aerospace, military, etc widely used.

Molybdenum web application:

I.

At the normal temperature of molybdenum in air and water are stable, are no effect of hydrochloric acid, hydrofluoric acid, nitric acid and alkali solution.

II.

Used in a vacuum environment, service life is not coated with molybdenum very long. Molybdenum mesh is completely stable in pure hydrogen, argon and helium. Molybdenum and hydrogen to melting temperature it will not occur chemical reaction. But the molybdenum heating in hydrogen, can absorb a portion of the hydrogen generated solid solution. For example, 100 grams of metal molybdenum can dissolve 0.5 cubic centimeter of hydrogen. The properties of molybdenum in many application in electric furnace proved this point.In carbon dioxide, ammonia and nitrogen, until about 1100 ℃ molybdenum network still has considerable enthusiasm.

Molybdenum net of choose and buy standard is as follows:

MESH(inch) | Wire diameter(mm) | Aperture (mm) | Maximum width(m) |

10 | 0.60 | 1.94 | 1.60 |

20 | 0.40 | 0.87 | 1.60 |

30 | 0.30 | 0.55 | 1.60 |

40 | 0.23 | 0.40 | 1.60 |

50 | 0.20 | 0.31 | 1.60 |

60 | 0.15 | 0.27 | 1.60 |

70 | 0.12 | 0.24 | 1.60 |

80 | 0.13 | 0.19 | 1.60 |

90 | 0.12 | 0.16 | 1.60 |

100 | 0.10 | 0.15 | 1.60 |

120 | 0.09 | 0.12 | 1.60 |

150 | 0.063 | 0.11 | 1.60 |

180 | 0.053 | 0.01 | 1.60 |

200 | 0.053 | 0.07 | 1.60 |

Special specifications can be produced according to customer requirements | |||

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Molybdenum Wire Mesh

Molybdenum

Molybdenum Wire

Spraying Molybdenum Wire

White Molybdenum Wire

Molybdenum Plate

More>>